Emerald Guitars Factory Tour

Opening Times

Tours: Jan- Dec: Mon – Fri, 9.30am to 4.00pm

Retail Store: Jan- Dec: Mon – Fri, 9.30am to 4.00pm

Closed Bank Holidays

Guitar Gallery

Imagine the thrill of being in on the behind the scenes creation of Emerald Guitars. There is something uniquely special about having a guided tour in Emerald Guitars NEW Guitar gallery tour. You will have the opportunity to view each guitar in Emerald Guitar’s Collection – hearing each guitar’s story of their unique journey from the dream, their creation, to the musicians playing them.

And our Emerald Tour doesn’t stop there –

Why not include a tour of our factory and see how Emerald Guitars are created – While we use a modern and high tech material our guitars are still very much hand made. We have a highly skilled team of craftsmen that spend many hours on every guitar refining every detail to give you a guitar that has been designed with passion and crafted with Love

Why not try our player experience

Book Factory Tour

For Group Discounts of 14 or more people contact sales@emeraldguitars.com for more information

Where to find us

Emerald Guitars,

Cavanacaw,

St Johnston,

Co. Donegal,

Ireland.

F93 XP82

Why not try our player experience

Factory Tour

The production process of every Emerald Guitar is a journey and on our tour you get to witness the transformation of raw materials from one state to a stunning BESPOKE guitar. Our tour spans every aspect of manufacturing from cutting the patterns, through the manufacturing processes, packaging of the final product, shipping, and dispatch.

Cutting Department

Production starts with the cutting process and in the cutting department you will see our Master Cutters at work. Utilising masterful skills our Cutter relies on these and dexterity to cut each individual guitar pattern, applying the exact pressure to make the cut without damaging the integrity of the carbon

Veneer Library

The veneer library holds our unique veneer selection – We love the look of carbon fibre but we also want to make guitars that are as unique as the musicians we build them for. Emerald guitars created and refined the process of fusing a very thin sheet of real wood veneer to the top of our guitars during the moulding process which gives a beautiful soundboard that has all the structure and strength of carbon fibre with the unique beauty of exotic wood.

Mould Room

The mould room where you witness the cut patterns brought together – Emerald have refined their unique one piece moulding technology that allows the entire guitar to be moulded together in one piece. The entire neck and body are moulded together in one piece giving a guitar that is incredibly strong and stable with no joints to fail and this in turn makes a guitar with incredible resonance and sustain.the ancient art of mould making.

Prep Department

Once removed from the ovens the refining process begins here – fretting, inlays etc are added and this is where the instrument starts to form and the guitars begin to take shape. Our guitars are carefully inspected at each stage of production to ensure each piece meets our exacting standards. With six stringent inspection areas, only pieces that satisfy these standards make it to the next stage of production.

Painting Booth

Here we have our priming booth and painting booth – our bespoke colours and shading are added to the guitars by our very talented painter, and then go to the oven to be cured overnight.

Hand Polishing/ Buffing Platform

The next part of your journey is the polishing department. Here each guitar can spend between 4 and 6 hours polishing and buffing to give it the high quality shine our customers have come to know.

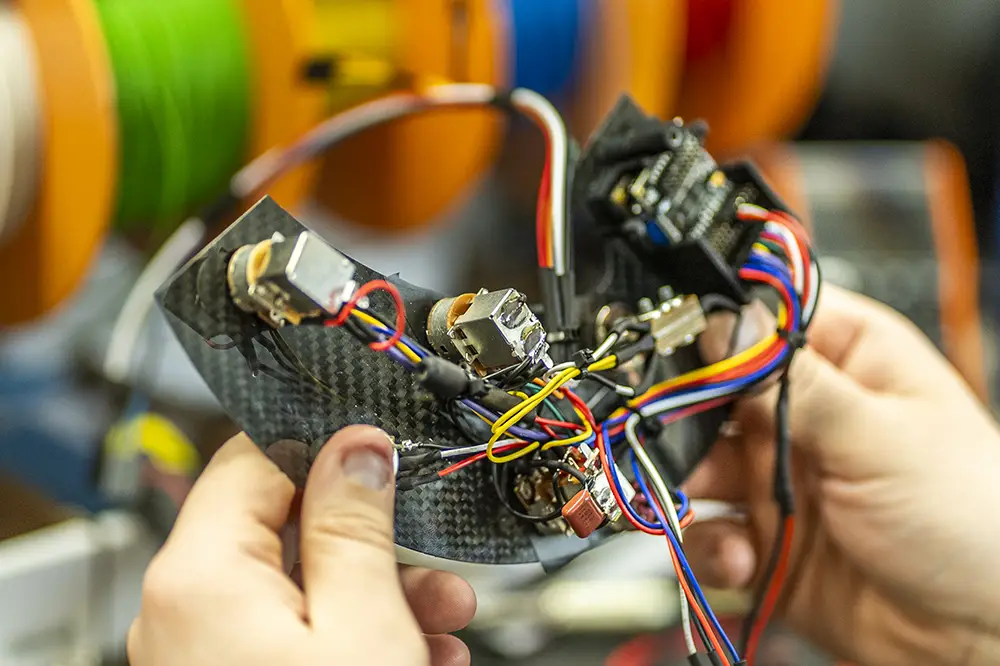

Electronics Assembly Department

Electronics Assembly – Here custom made electronics are created for each guitar – Final Set Up – We have developed a suite of pickup options that gives you a wide array of innovative options to meet any playing style and stage. We partner with Fishman, LE-Baggs and Graphtech to bring you pickup choices that have been developed specifically for our unique range of guitars and added at this final stage the Guitar is now complete.

Pleking Suite

Final Stage of Production – Quality Control – Plek Perfect Frets

Emerald have invested heavily in the Plek technology that allows us to scan every fretboard while it is under tension and tuned to pitch and then using some very innovative software allows us to machine the frets to the perfect tolerance taking into account fret radius, action height, neck relief and string gauge.

Photography Studio/ Media Suite

Photography Studio/media – Every Emerald Guitar is photographed here – Custom-built guitars for the customer gallery on the website and Stock guitars all go online after being photographed. Filming tech films, guitar demos, or highlighting certain features of Emerald Guitars for social media are done in our media suite.

Weekly Shipping Videos

A highlight on our website is the shipping videos so join us in the shipping room where every week we film and walk you through the latest carbon fiber guitars shipping worldwide and give exclusive updates on all things Emerald Guitars

Departures – Shipping /Tech/Support

Our guitars are carefully inspected at each stage of production to ensure each piece meets our exacting standards. With six stringent inspection areas, only pieces that satisfy these standards make it to the next stage of production. Departures – Shipping/Tech/Support Quality Control – For customers to be satisfied, they need to receive what they ordered, in the correct quantity, to the required standard, at the expected date and time.

Retail Store

Our opulent Retail Store gives you the opportunity to remember your unforgettable day by choosing a piece of the Emerald experience to take home. The retail store represents our on-line catalogue of quality gifts including the infamous Emerald mugs and it is currently being added too.

Players Suite

Follow up your Tour up with a session in “The Players Room” where you have the opportunity to try any of the Emerald Guitars from our collection for yourself – we have our own team of talented musicians on site should you require a demonstration – that can also be arranged prior to visit if you wish.

Or Simply just visit and enjoy an hour long session to jam on any Emerald model, a unique experience for all guitar lovers.

Visit the Players Suite page here to make a booking

3D Guitar Builder

In our “The Players Room” we also offer you the experience of 3D Guitar Builder – where you Choose a Model to Start Building a bespoke guitar – Designed By You, Built By Us!

Our 3D builder tool is an industry leading interface that allows you to see each model in 3 Dimensions and zoom in on any detail from any angle to give you an unprecedented understanding of the details of our guitars. You can also select from many custom options to build the guitar of your dreams and see that dream guitar in 3D before you buy

Emerald Guitars Music Tour

Experience the magic of Donegal with Emerald Guitars

Join Emerald Guitars, the longest-running carbon fibre guitar company with over 25 years of innovation, on a journey through breathtaking landscapes and soulful music that capture the spirit of this enchanting region.

A truly unique and luxury experience as Kim and Alistair take you on a guided tour of their favourite places, meet their favourite musicians and stay in one of their favourite luxury country estates – Rockhill House . Where you will enjoy fine dining and modern amenities within the historic Rockhill House Estate, nestled amidst 100 acres of lush countryside.

May & September bookings are available HERE